We use cookies to offer our visitors a better experience and personalized content. We also may share information about your use of our site with our social media, advertising and analytics partners.

By continuing to browse the site you are agreeing to our Privacy.

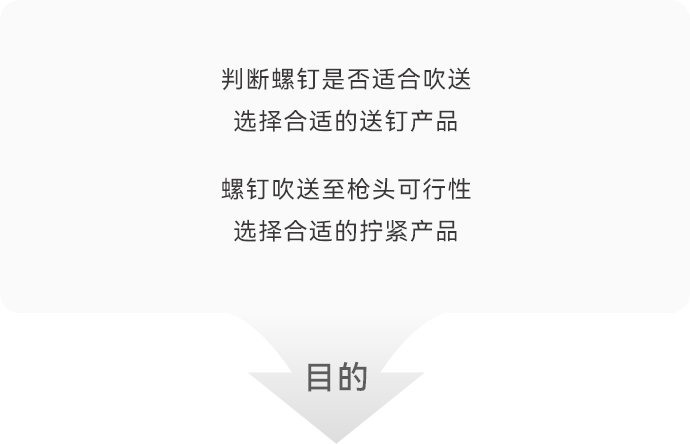

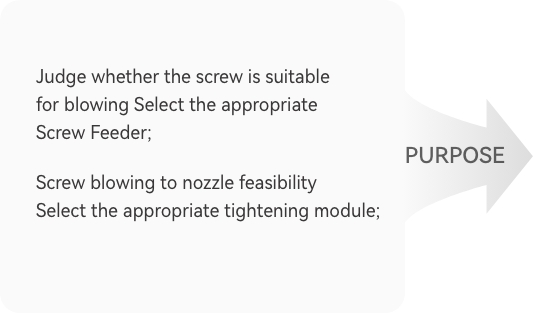

Know more about screws

Select a stable &

suitable Screw Feeding & Tightening System

suitable Screw Feeding & Tightening System

Screw Application

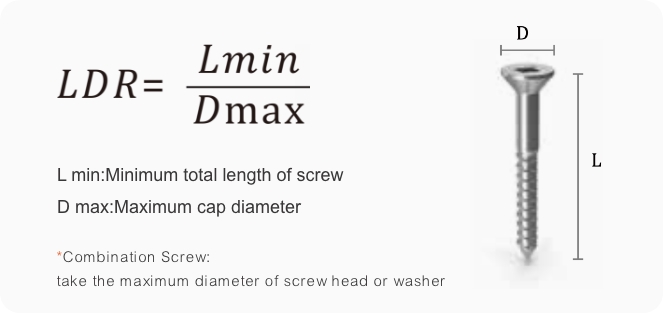

The Effect of LDR:

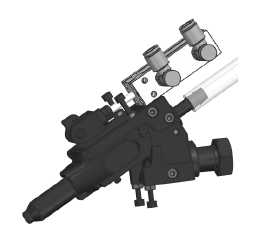

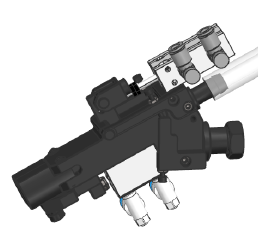

Select Stable & Suitable

Screw Feeding & Tightening System

Tolerance According To Screw Size:

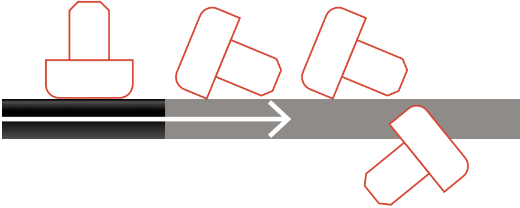

Feasibility Of Screw Feeding

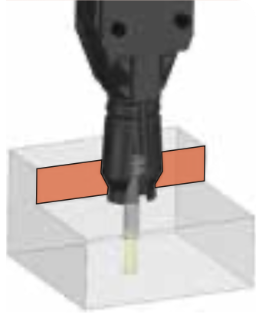

LDR≤1.3

Top-heavy, not easy to get into feed rail

Top-heavy, not easy to get into feed rail

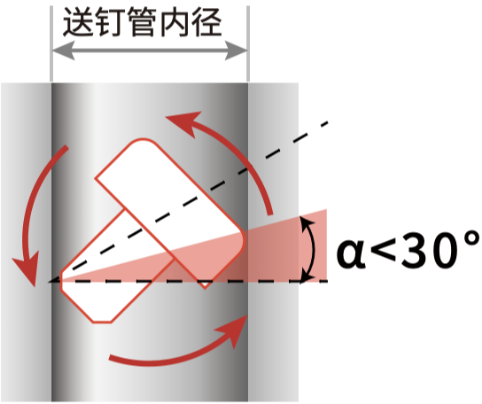

there is a risk that the screws could jam inside the screw blowing tube

Low probability of screws enter- ing the track not

suitable for blow screw

suitable for blow screw

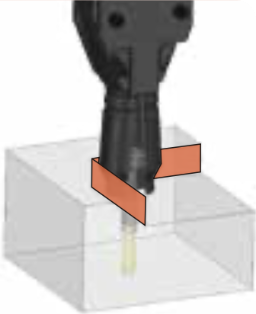

LDR 1.1~1.3

Easy to jamming in the screw blowing tube

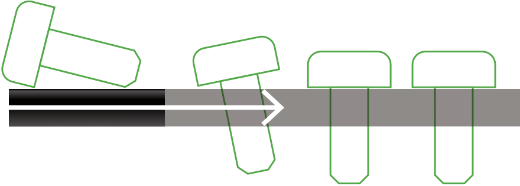

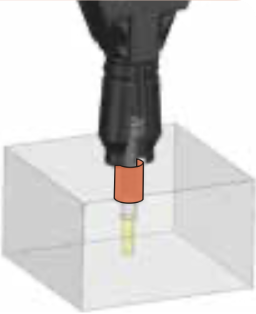

LDR>1.3

Passed smoothly

High probability of screws entering

the track suitable for blowing

the track suitable for blowing

LDR>1.3

Stable blowing

Know more about operating conditions

Make sure that automatic screw feeding and tightening are more efficient

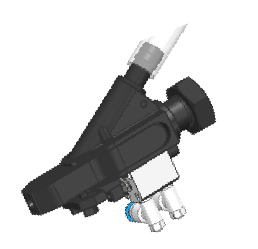

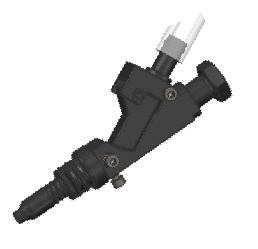

Tightening Position

No interference

One-side interference

Multi-sides interference

Countersink

Nozzle Analysis

Recommend L/D range

*1 Only tightening module executing time, screwdriver tightening time is not included.

*2 Screw blowing is avaliable.