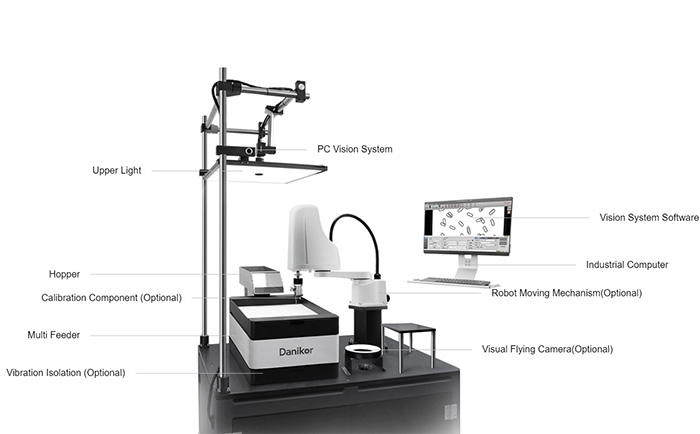

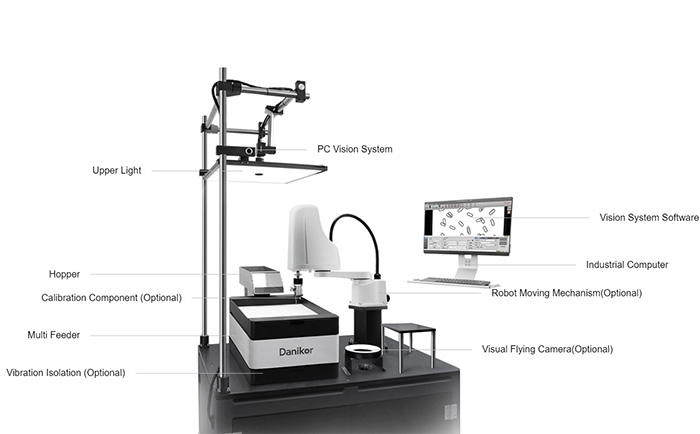

The Multi Feeder System is a highly flexible and customized automatic part feeding mechanism, which effectively solves the problem of metal/plastic parts feeding difficulties caused by different parts sizes and shapes. It is suitable for the application scenarios of rapid material replacement and frequent switching, and is widely used in the intelligent manufacturing field and automated production line of electronics, semiconductors, automobiles, workpieces and other industries.

Working principle

First, the materials are put into the bin and fed into the Multi Feeder System through the vibration of the bin. The multi feeder is composed of four voice coil motors, and the corresponding vibration points of the four motors are distributed at the four corners of the multi feeder.

By controlling the vibration frequency of the voice coil motor, the parts move in any direction along the surface of the tray, and the parts are separated and moved in the specified direction by vibration/flipping, etc., and the parts are arranged by rapid vibration dispersion.

Then the vision system CCD captures the material tray to pick up the appropriate part shape and position information in the tray, and sends the coordinate data to the robot.

Finally, based on the coordinate data sent by the vision system, the robot grabs parts from the surface of the feeding tray for array swing or assembly.

Detection principle

1. Testing requirements

Multiple sample locations on the multi feeder are visually identified and the coordinates of the corresponding sample are then output to the controller for the next array swing or assembly process.

2. Software algorithm

The system creates a sample shape template and then sets the number of samples to be identified at a time according to the project requirements.

multi feeder operation mode: After the vibration mode, the camera collects images, intelligently identifies the position of multiple samples, displays the position information of the identified samples, and calculates the output of the day.

multi feeder stop operation mode: stop the vibration of the flexible vibration disk and stop the operation of CCD.

Internal structure principle

The internal structure of Danikor multi feeder mainly consists of two parts: the main structure of the multi feeder material and the internal driver. There is an encouraging driving structure inside the body of the multi feeder material, and the coupling of the encouraging source at each position can complete the movement and turnover of the material on the plate in different directions.

There is a kinetic energy driving structure inside, and the coupling of kinetic energy at each position can complete the movement and reversal of the material on the tray along the arbitrary direction. Its role is to replace the traditional multi feeder, complete the material selection and front and back identification of shaped materials, does not damage the appearance of the material, can meet the small batch of various types of production needs, through the vibration of the disordered workpiece actively orderly directional arrangement, accurate delivery to the next process.